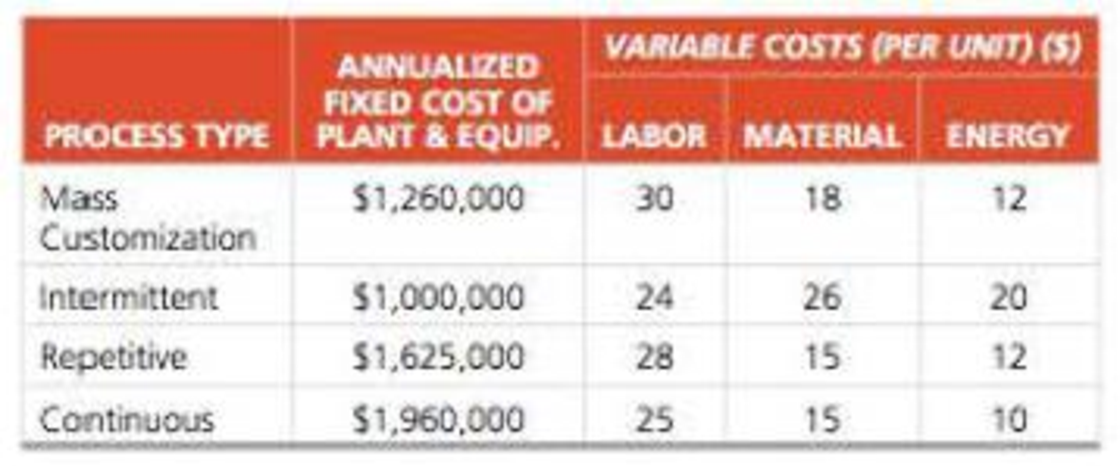

Metters Cabinets, Inc., needs to choose a production method for its new office shelf, the Maxistand. To help accomplish this, the firm has gathered the following production cost data:

Metters Cabinets projects an annual demand of 24,000 units for the Maxistand. The Maxistand will sell for $120 per unit. a) Which process type will maximize the annual profit from producing the Maxistand?

b) What is the value of this annual profit?

a)

To determine: The process type that will maximize the annual profit by producing the Maxistand.

Answer to Problem 9P

The process type that will maximize the annual profit by producing the Maxistand is the intermittent process.

Explanation of Solution

Given information:

| Process type | Annual fixed cost of plant & equip |

Variable costs (Per Unit) ($) | ||

| Labor | Material | Energy | ||

| Mass customization | $1,260,000 | 30 | 18 | 12 |

| Intermittent | $1,000,000 | 24 | 26 | 20 |

| Repetitive | $1,625,000 | 28 | 15 | 12 |

| Continuous | $1,960,000 | 25 | 15 | 10 |

Annual demand = 24,000 units

Maxistand selling price = $120 / unit

Calculation of number of units:

Let ‘x’ be the number of units. The units is calculated by multiplying annual fixed cost with ‘x’ and summing with the total variable cost and equating it with multiplying the Maxistand selling price with ‘x’.

Mass customization:

Intermittent:

Repetitive:

Continuous:

Identifying least cost process at x = 24000 units:

The least cost is calculated by multiplying variable cost with the value of ‘x’ and summing it with the annual fixed cost.

Mass customization:

Intermittent:

Repetitive:

Continuous:

The cost is lower for intermittent process ($2,680,000) with the break-even point of 20,000. The intermittent process will increase the annual profit.

Hence, the best process is the intermittent process.

b)

To determine: The annual profit by following the intermittent process.

Answer to Problem 9P

The annual profit is $200, 000

Explanation of Solution

Given information:

| Process type | Annual fixed cost of plant & equip |

Variable costs (Per Unit) ($) | ||

| Labor | Material | Energy | ||

| Mass customization | $1,260,000 | 30 | 18 | 12 |

| Intermittent | $1,000,000 | 24 | 26 | 20 |

| Repetitive | $1,625,000 | 28 | 15 | 12 |

| Continuous | $1,960,000 | 25 | 15 | 10 |

Annual demand = 24,000 units

Maxistand selling price = $120 / unit

Calculation of number of units:

Let ‘x’ be the number of units. The units is calculated by multiplying annual fixed cost with ‘x’ and summing with the total variable cost and equating it with multiplying the Maxistand selling price with ‘x’.

Mass customization:

Intermittent:

Repetitive:

Continuous:

Identifying least cost process at x = 24000 units:

The least cost is calculated by multiplying variable cost with the value of ‘x’ and summing it with the annual fixed cost.

Mass customization:

Intermittent:

Repetitive:

Continuous:

Calculation of annual profit:

The annual profit is calculated by multiplying the selling price with annual demand and subtracting it from the cost of the intermittent process.

The annual profit is $200, 000.

Want to see more full solutions like this?

Chapter 7 Solutions

Principles Of Operations Management

- Virginia College promotes a wide variety of executive training courses for firms in the Arlington, Virginia, region. Director Wendy Tate believes that individually written letters add a personal touch to marketing. To prepare letters for mailing, she conducts a time study of her secretaries. On the basis of the observations shown in the following table, she wishes to develop a time standard for the whole job. Element Customizing letter Labeling envelope Stuffing envelope Sealing, sorting Performance Rating 85% 100% 95% 125% 1 2.5 0.9 0.3 0.9 Observation (minutes per cycle) 4 2.1 0.7 0.3 0.9 2 3.5 0.8 0.4 3.0 3 2.8 0.6 2.0* 0.8 5 2.7 3.2* 0.5 4.3^ 6 3.3 0.6 0.6 1.0 *Disregard-secretary stopped to answer the phone ^ Disregard-interruption by supervisor The college uses a total allowance factor of 12%. Tate decides to delete all unusual observations from the time study. The standard time for this process = minutes (round your response decim places).arrow_forwardDuring Covid-19 pandemic, CV. SBK experienced a serious revenue declining problem. The goal of CV SBK is to measure their performance in order to improve their revenue. Based on the information above, Develop a SCM performance measurement dashboard for CV SBK using a Process-based framework approach (Chan & Qi, 2003). You may add assumptions if needed.arrow_forwardFor Process Planning, provide a comprehensive description, what benefit it may offer to the ABC Corporation, and what needs to be done in order to successfully implement this topic into the ABC Corporation. For Process Planning, integrate appropriate biblical references. Explain how Process Planning magnify God’s plan for you?arrow_forward

- Which three process strategy principles are very critical ?arrow_forwardGive one product and identify its system boundary for LCA studies in accordance to the ISO 14044.arrow_forwardCreate the process diagram 4. DESIGN and DRAW a high level “as-is” process diagram depicting how a trade would be made, under your proposed structure. The diagram should be for the model you are supporting and should show the bands, process flows, roles, decisions and/or cross functional interactions required. Summarise and make Recommendations 5. Summarise the information shared thus far, and discuss TWO findings about your analysis from your management level that can be used to decide on the final company structure. Make TWO recommendations to support either a change or no change, in the company structure. Only credible sources should be used.arrow_forward

- Marco, a plumbing, heating and AC company located in California, has a simple butpowerful product strategy: ‘Solve the customer’s problem no matter what, solve theproblem when the customer needs it solved, and make sure the customer feels goodwhen you leave’. The company guaranteed, same day service for customers requiringit. The company provides 24 x 7 services at no extra charge for customers whose ACdies in hot summer Sunday or whose toilet overflows at 2.30 AM. The companyguarantees the price of a job to the penny before the work begins. Whereas mostcompetitors guarantee their work for 30 days, Marco guarantees all parts and labourfor one year. The company assesses no travel charges as “it’s not fair to charge customers for driving out.” The company owner says: “We are in an industry thatdoesn’t have best reputation. If we start making money our main goal, we are introuble. So I stress customer satisfaction; money is a by-product.”The company uses hiring, ongoing training and…arrow_forwardYour company is planning to organize a workshop on quality managem ent. There are 10managers in your company all of whom have received free passes for the workshop. These passes would allow five free seats to the indivi duals. The managers from other companies can also attend the event, however they need to pay $60 per pers on. All the people attending the workshop would get complimentary lunch, snacks and parking facilities without any extra fees. There are certain costs associated with the workshop including lunch cost of $5 per person, snacks cost of $3 per person, parking cost of $4 per person, speakers cost of $800 per speaker (total 5 speakers are used), registrati on fee of $7.50 per person, and auditorium cost of $200. Approximately how many managers from outsi de the company require to attend the meeting so that the workshop would reach break-even? (A) 128 (B) 210 (C) 365 (D) 517arrow_forwardmultiple choice questions: One of success process strategies philosophies is the process foundation, which: Select one: a. Creates the supply chain of organisation to satisfy and enhance competitiveness b. Fulfills process characteristics and strategic match c. Includes subcontractors due to their link to organisational processes d. None of these e. All of these Question 4 The periodic counting system records immediate updates of inventory withdrawals Select one: a. False b. True Question 5 The decision to configure assets according to product or process rely on the following, except: Select one: a. Variability b. Velocity c. Flexibility d. Quantities Question 6 ___________________ utilises statistical modelling to predict future sales figures, often taking into account current and historical trends. Select one: a. Aggregate planning b. Quantitative forecasting c. Sales forecasting…arrow_forward

- Describe the role of a Business Process Model and Notation (BPMN) in requirement analysis for business process improvement. How does it enhance clarity and communication?arrow_forwardDBS is also expecting the demand for its top-of-the range devices to increase further from the next year. Given the increase in annual requirement, the production manager is contemplating to start manufacturing the special components in-house to save costs rather than sourcing them from outside. Given the current purchase price of $9000 per unit, what will the average annual requirement need to be in order to justify making the components in-house if the variable cost of making is $6750 per unit and an upfront fixed cost of $55,000,000 is needed to procure the necessary plant and equipment? However, in the event that the expected increase in demand does not materialize and the demand is actually forecast to drop to 20,000 units next year, then what will be the maximum price per unit that DBS would be willing to pay to the supplier in order to continue buying from them? Going forward, if it is found to be a better decision to make the components in-house, DBS will then need to…arrow_forwardJYP is a hypermarket chain that operates throughout China, with 25 locations and 800 employees ranging from store workers to the CEO. JYP I operates in a very competitive environment with numerous other companies. As a result, improving performance is vital in order to achieve the goal of being the number 1 hypermarket chain in the country. The goal must be met while taking into account the relatively high worker turnover rate in this area. a)Explain how the Maslow Hierarchy of Needs application may be of use at JYP. b)Explain the application of Performance Management System at JYP.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.